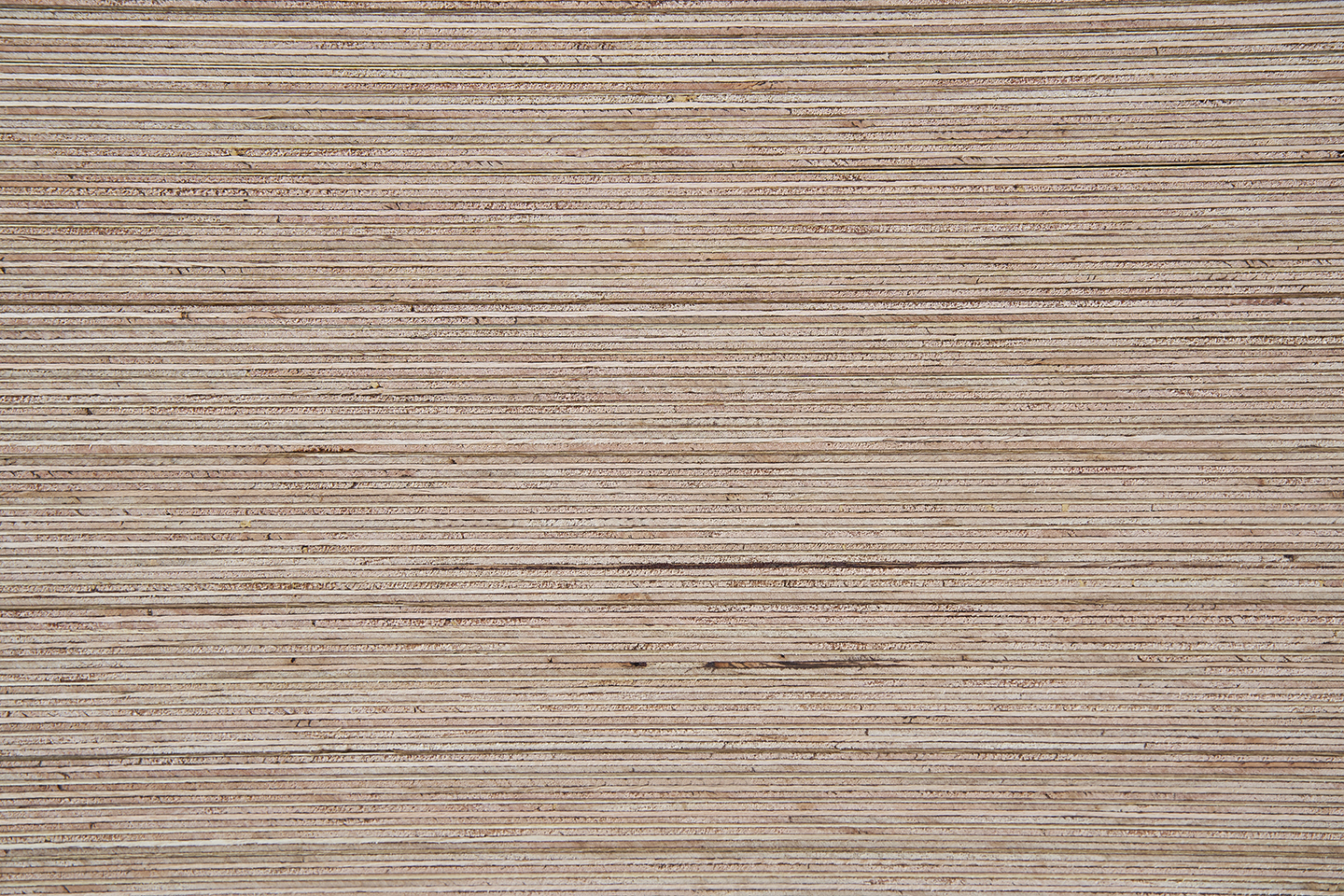

Plywood for flooring substrate

Product Parameters

|

Core |

Eucalyptus ,lauan |

|

Face/back |

lauan |

|

GLUE |

WBP or Melamine Formaldehyde emission reaches the highest international standard (Japan FC0 grade) |

|

SIZE |

915X1830X12mm, 1220X2440X5.8/7.0mm Special specifications can be customized according to user needs |

|

MOISTURE CONTENT |

≤12% The bonding strength reached the T1 class standard according to the Japanese soaking and stripping method |

|

THICKNESS TOLERANCE |

≤0.3mm |

|

LOADING |

8pallets/21CBM for 1x20’GP 18pallets/40CBM for 1x40’HQ |

|

USAGE |

Mainly used for geothermal floor substrate |

|

MINIMUM ORDER |

1X20’GP |

|

PAYMENT |

T/T or L/C at sight. |

|

DELIVERY |

about 15- 20days upon receipt of the deposit or L/C at sight . |

|

FEATURES |

1.Product structure is reasonable, less deformation, smooth surface2.can be cut into small size for reusing |

plywood offers several advantages, including

Plywood can be a suitable flooring substrate for certain types of flooring, such as hardwood, carpet, and vinyl. However, the suitability of plywood as a substrate will depend on a number of factors, including the grade of the plywood, the thickness of the plywood, and the spacing of the joists supporting the plywood.

Plywood is a popular choice for flooring substrates because it offers several advantages:

Strength and Durability: Plywood is a strong and durable material, making it ideal for flooring substrates. It can withstand heavy foot traffic and is less likely to warp or bend compared to other types of wood.

Stability: Plywood is made by gluing layers of wood together in alternating grain patterns, which creates a stable and flat surface. This stability helps prevent flooring from cupping, warping, or twisting over time.

Resistance to Moisture: Plywood is also resistant to moisture, making it suitable for use in damp environments such as bathrooms or basements. Plywood can withstand exposure to moisture better than other wood materials, reducing the risk of damage and mold growth.

Cost-Effective: Plywood is generally more cost-effective than other types of wood flooring substrates, such as solid wood planks. It is also easy to work with, which can save time and money during installation.

Overall, the strength, stability, moisture resistance, and cost-effectiveness of plywood make it a popular choice for flooring substrates.