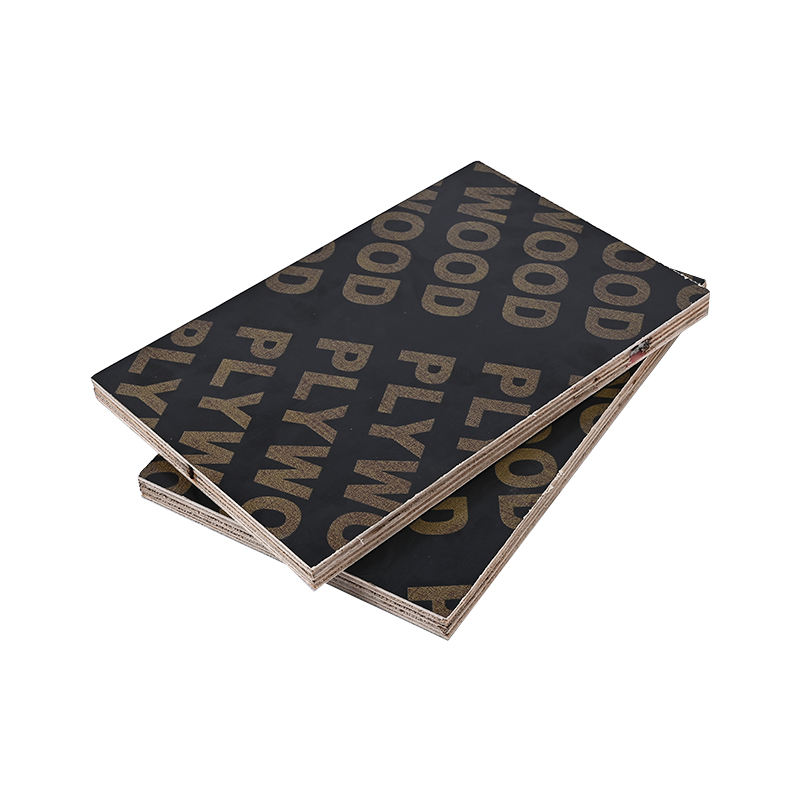

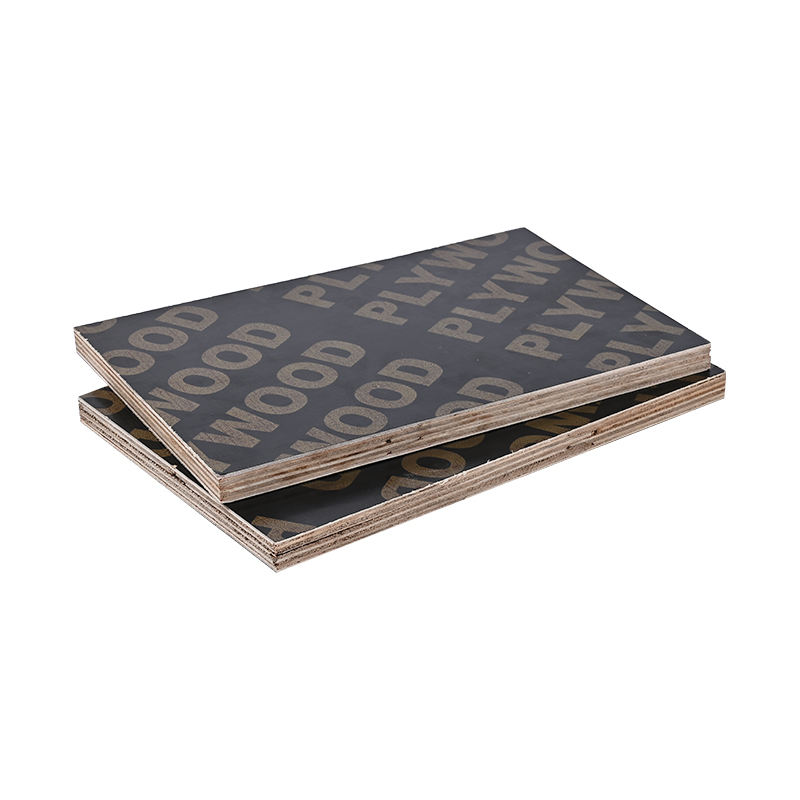

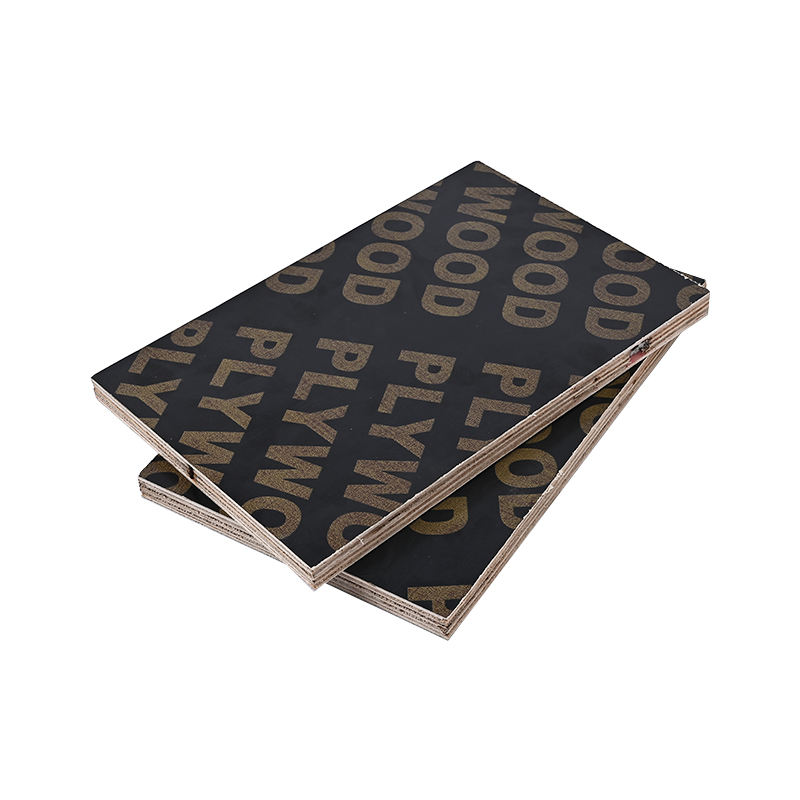

Film faced plywood for Building Templates

Product Parameters

|

Material |

Eucalyptus,poplar, hardwood, birch, pine, combi , and so on |

|

Face |

Black Film, Brown Film, Red Film (Film can be printed with requested logo) |

|

Glue |

WBP Formaldehyde emission reaches the highest international standard (Japan FC0 grade) |

|

SIZE |

1220X2440mm |

|

Thickness |

12mm/15mm/18mm/21mm/etc Special specifications can be customized according to user needs |

|

MOISTURE CONTENT |

≤12%, glue strength≥0.7Mpa |

|

THICKNESS TOLERANCE |

≤0.3mm |

|

LOADING |

8pallets/21CBM for 1x20’GP 18pallets/40CBM for 1x40’HQ |

|

USAGE |

Apartment, Farmhouse, Building Construction |

|

MINIMUM ORDER |

1X20’GP |

|

PAYMENT |

T/T or L/C at sight. |

|

DELIVERY |

about 15- 20days upon receipt of the deposit or L/C at sight . |

|

FEATURES |

1.Smooth face/back, durable and strong,premium core veneer, excellent WBP glue bonding quality.+ edges sealed with water proof painting2. can be cut into small size for reusing |

Film faced plywood offers several advantages, including

Film faced plywood is a type of plywood that is commonly used in construction and formwork applications. Here are some advantages of film faced plywood:

Durability: Film faced plywood is made with a high-quality film that is applied to the surface of the plywood. This film protects the plywood from moisture, wear and tear, and other forms of damage, making it more durable than traditional plywood.

Resistance to moisture: The film on film faced plywood is designed to resist moisture, making it ideal for use in humid or wet conditions. This makes it a popular choice for use in construction projects that involve pouring concrete, as it can withstand the moisture from the wet concrete.

Versatility: Film faced plywood is available in a range of sizes and thicknesses, making it suitable for a wide variety of applications. It can be used for formwork, flooring, wall panels, and other structural applications.

Cost-effective: Although film faced plywood is more expensive than traditional plywood, it is often more cost-effective in the long run. Its durability and resistance to moisture mean that it is less likely to need to be replaced, which can save money on maintenance and replacement costs.

Easy to clean: The smooth surface of film faced plywood makes it easy to clean, which is important in construction projects where cleanliness is necessary to prevent defects in the finished product.

Environmentally friendly: Film faced plywood is made from renewable resources and is recyclable, making it an environmentally friendly choice for construction projects.